Digital Conversion of a Hornby Locomotive to Hornby DCC

Fitting a digital control chip to your Hornby locomotiveAbstract

Tri-ang and Hornby have been producing OO/HO scale model trains for many years and very nearly all of them can be adapted or converted to operate on the latest Hornby Digital Command Control (DCC) or digital control system. Hornby have available all the parts needed and the conversion process for a locomotive seems very simple. This article points out the best process to convert a Hornby locomotive to digital control to give the best level of reliability of the converted locomotive.

Introduction

Over the years, at the time of writing nearly 50 of them, Tri-ang and Hornby have been producing OO/HO scale model trains for all to enjoy with seemingly little change. This would tend to indicate that any Hornby locomotive can be converted to operate on the Hornby DCC system. However, this isn't the case as there needs to be some distinct requirements for successful installation of a DCC digital chip into a Hornby locomotive. To simplify the installation of a DCC microprocessor into a Hornby locomotive we have developed the generic process detailed below. Please note that some specific Hornby locomotives may need some specific actions to enable successful DCC conversion.

How does digital control work?

The Hornby DCC system gives you the ability to run and control multiple locomotives on the same electrical circuit independently of each other. To do this the digital controller is connected to the track in order to supply power and the high speed digital control signals to your locomotives. These digital signals are sent from the controller, through the track, and into the locomotive where it is then interpreted by a digital chip. The digital chip then provides the required electrical current to the motor as instructed by the digital signals. The digital chip can also control the locomotives lights and sound the horn if fitted.

The key point for conversion of Hornby locomotives to DCC is that the chip electrically connects to the track, both LH and RH side, the chip also connects electrically to both poles of the motor. There is no direct electrical connection from the track to the motor. Indeed there MUST NOT be any direct electrical connection from the track to the motor. This would render the converted locomotive inoperable and in most cases permanently damage the digital chip.

Step 1. Your Hornby locomotive

The locomotives produced by Tri-ang and Hornby appear very similar from the beginning the the current offerings but there are some significant differences. The 2 key points in assessing whether or not your Hornby locomotive can be converted to DCC are; can the motor be completely electrically isolated from the track and the amount of electrical current drawn by the motor.

Electrical isolation of the motor

In order to operate in the conventional analogue locomotive, electrical current must flow from one track rail through the motor and back to the other track rail. Over the years Hornby has been very "clever" in how this is done. The first step in assessing a locomotive for digital conversion is the ability to totally isolate both poles of the motor from the track. For some locomotives this would be very simple for others probably impossible in practical terms. For example the vertically mounted motor used in many of the early 3 rail locomotives would be very difficult to fully isolate the chassis side as the wheel axles connect to the chassis and the motor brush housing also fits directly into the chassis. There is no means of electrical isolation available.

Other locomotives and motors are easy to isolate. For example the very common X.03 or X.04 motor can be easily isolated by fitting an insulation sleeve to the chassis motor brush in the same way a sleeve is already fitted to the live motor brush.

Once you are sure you can completely isolate the motor from the track connections, both poles, then you can consider which digital chip you should use.

DCC Ready locomotives are fitted with a socket ready to accept a DCC decoder. These locomotives require a DCC decoder to be fitted to the socket in order to work on a DCC controlled layout.

Step 2. Which digital chip to use

There are 3 different conventional digital chips available from Hornby plus the digital sound chip which is difficult to source as, at the time of writing, is not supported by Hornby.

The first chip is the one fitted by the factory for many of the DCC fitted locomotives supplied directly by Hornby. There are 2 key points about this chip. The first point is that this chip is amazingly unreliable and doesn't always meet the specified DCC standard. The second point is that this chip is not offered by Hornby for the DCC conversion of locomotives, see point 1. Shame on you Hornby.

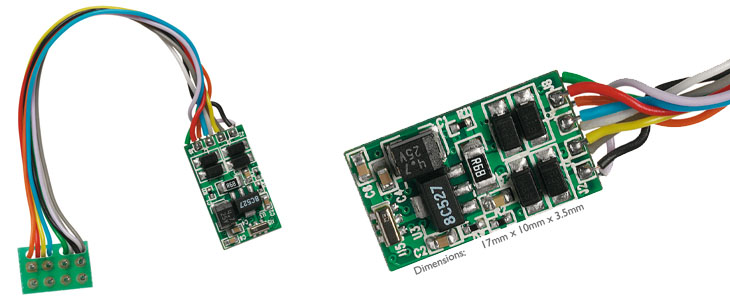

The second chip is the standard R8249 decoder. This is a reliable chip that can be fitted to most modern locomotives fitted with the newer motors. Dimensions; 17mm x 10mm x 3.5mm (approx).

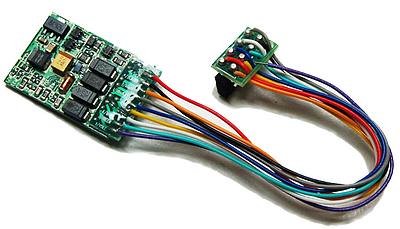

The third chip is the R8245 Sapphire decoder which provides 1 amp continuous current and shows signs it might even have some over current protection fitted. Dimensions; 23mm x 16.5mm x 6.5mm (approx).

The digital sound chip is similar in capability as the standard R8249 decoder but can also be connected to a small speaker to produce very realistic and believable sounds as your locomotive operates. This chip is not supported by Hornby and needs specialised support to install the correct sound files.

So, there are effectively only 2 chips to choose from; the standard R8249 decoder and the R8245 Sapphire decoder. The key difference is the electrical current capability of the chips which indicates that chip selection depends almost exclusively on the motor fitted to your Hornby locomotive. Below is a table of the motors used and the most suitable chip to use.

Dublo 3 rail vertical motor R8245 Sapphire decoder * Dublo 2 rail vertical motor R8245 Sapphire decoder * X.03 and derivatives R8245 Sapphire decoder X.04 R8245 Sapphire decoder Ringfield 3 pole R8245 Sapphire decoder Ringfield 5 pole R8245 Sapphire decoder Mabuchi (all types) R8249 standard decoder ** Type 7 R8249 standard decoder ** * Only if the ground side motor brush can be electrically isolated from the chassis.

** The R8245 Sapphire decoder can be used if desired.

Step 3. Service your Hornby locomotive

We've seen it stated that fitting a digital chip to a Hornby locomotive will improve the smooth running of the locomotive. Unfortunately this is simply not true. In fact the opposite is the reality. If your Hornby locomotive doesn't run well in analogue then it will be worse in digital. Remember, it's not just electrical power going to the digital locomotive there will also be high speed digital data which can be readily disrupted by poor electrical contact between the digital chip and the track.

Older Hornby locomotive motors as they age can consume more electrical current that specified. This is due to the discarded carbon powder from the motor brushes producing a partial electrical short circuit between the motor commutator segments.

Before converting your Hornby locomotive you MUST first complete a thorough service focusing on the electrical path from the track to the digital chip and on servicing and cleaning the motor. Once completely serviced and running very well in both directions in analogue only then can you consider converting your Hornby locomotive to DCC. Should your locomotive operate smoother and faster in one direction than the other then you should replace or dress the motor brushes as this is the most common cause of direction drive asymmetry.

Step 4. Understand the electrical current path in your Hornby locomotive

As stated earlier, Hornby has been very "clever" in arranging how the electrical current flows from one track rail through the motor and back to the other track rail. Generally the live side is easy to identify as this is isolated from the chassis and generally uses; contacts on the isolated wheels and wires that go to the motor contact.

On the older Hornby / Tri-ang locomotives the ground side can be more involved to establish. From the wheels the current generally goes to the axle and from the axle to the metal chassis of the locomotive. From the chassis to the motor contact varies from locomotive to locomotive. For example the X.03 and X.04 motors use the motor frame to connect from the chassis to the brush spring. The ringfield motors have used several solutions; a separate wire, the brush spring plate fixing screw and even a touch type connection from the chassis to the brush spring plate.

Some older locomotives can use multiple electrical ground paths from the track to the motor contact. Make sure you find them all.

Newer Hornby locomotives tend not to use the chassis of the locomotive for the ground side electrical path but use wheel contacts and wires just like the live electrical path.

Step 5. Electrical isolation

Once you've established the electrical current path from one track rail through the motor and back to the other track rail you can establish the best means of isolating BOTH sides of the motor. You should test this isolation one electrical path at a time. You should also take into account other electrical items fitted to your Hornby locomotive, for example, light bulbs and smoke generator heaters.

Light bulbs should stay on the track side of the digital chip and smoke generator heaters should be disconnected all together.

Step 6a. Fitting the digital chip (non DCC ready locomotive)

Once all the previous tasks have been done actually fitting the digital chip is fairly straight forward with only 4 electrical connections required, 2 to the track and 2 to the isolated motor connections.

- The first task is to protect the chip from electrical short circuit especially as the chassis of the locomotive may be connected to the ground side track rail. Carefully wrap the chip in insulation tape ensuring there's no static electricity about.

- The unused wires are also insulated to prevent unwanted short circuits.

- The location for the chip is identified depending on space available and to minimise wiring connections.

- Use a small drop of super glue to hold the chip in position.

- Connect the 2 motor wires to the motor contacts and insulate the connections. Orange and grey wires.

- Connect the 2 track side power feed wires to the locomotive live and ground contacts points and insulate the connections. Red and black wires.

- Visually inspect the installation to ensure there are no short circuits, especially on the motor side of the digital chip.

Pin 1 Motor connection 1 (live side) Orange Pin 2 Function output B (rear light) Yellow Pin 3 Function output C Green Pin 4 Track connection 2 (ground side) Black Pin 5 Motor connection 2 (ground side) Grey Pin 6 Function output A (front light) White Pin 7 Function positive common Blue Pin 8 Track connection 1 (live side) Red Step 6b. Fitting the digital chip (DCC ready locomotive)

Once all the previous tasks have been done actually fitting the digital chip is fairly straight forward with only the single plug connection to be made.

- The first task is to protect the chip from electrical short circuit especially as the chassis of the locomotive may be connected to the ground side track rail. Carefully wrap the chip in insulation tape ensuring there's no static electricity about.

- The unused wires are also insulated to prevent unwanted short circuits.

- The location for the chip is identified depending on space available and to reach the NMRA standard plug.

- Use a small drop of super glue to hold the chip in position.

- Identify the correct orientation for the NMRA standard plug Pin 1 to Pin 1. Remove the Jumper plug and plug in the NMRA standard plug of the digital chip.

- Visually inspect the installation to ensure there are no short circuits.

Step 7. Testing and operating

Once you're happy with the installation of the chip and are sure that there are no short circuit problems then it's time to test your converted digital Hornby locomotive. Set the speed controller to zero speed and place your locomotive onto the live rails. Any lights connected to the track side of the digital chip will illuminate immediately. The locomotive should not attempt to drive.

Program the identity of the digital chip in the locomotive in the usual way. Ensure the correct lane is selected and slowly increase the speed controller. At first the locomotive will hum a little and then start to move in the desired direction. Increase to a moderate speed and then stop the locomotive.

Reverse the direction of travel on the controller and test again. The locomotive should operate the same in both directions. Remove the locomotive from the track, re-fit and body or top covers to complete the locomotive and test again as before.

Your digital Hornby locomotive can now join the rest of your stable and be used as normal.

About the author:

Gary Harding has been working with Hornby model locomotives for over 35 years and now operates Hornby Train Restorations in the UK. Hornby Train Restorations is a Worldwide internet based business that offers for sale high quality Hornby model locomotives, coaches, wagons and Hornby spares from the 1960s to the present day. All the restoration work is carried out to the highest standards with the highest quality parts available. Only the best locomotives are selected and the final result is a locomotive that is genuinely like new.

Further help and advice relating to this article or Hornby model locomotives in general can be found at:

http://www.hornby-railway-trains.co.uk